5 axis CNC Milling / Mould Trimming

Thermoforming Mould Making with CNC Milling Machines

Trimming of laminated timber moulds, vacuum formed moulds, carbon fibre moulds

Mould it

Create custom mould to minimise cutting time. Timber moulds, carbon fibre moulds, plastic moulds

Trim it

5-axis machining provides complex shapes milled in a single setup for increased productivity

Rock it

Increase your productivity and make prototypes at your desk

Formwork Setup

Prepare the mould

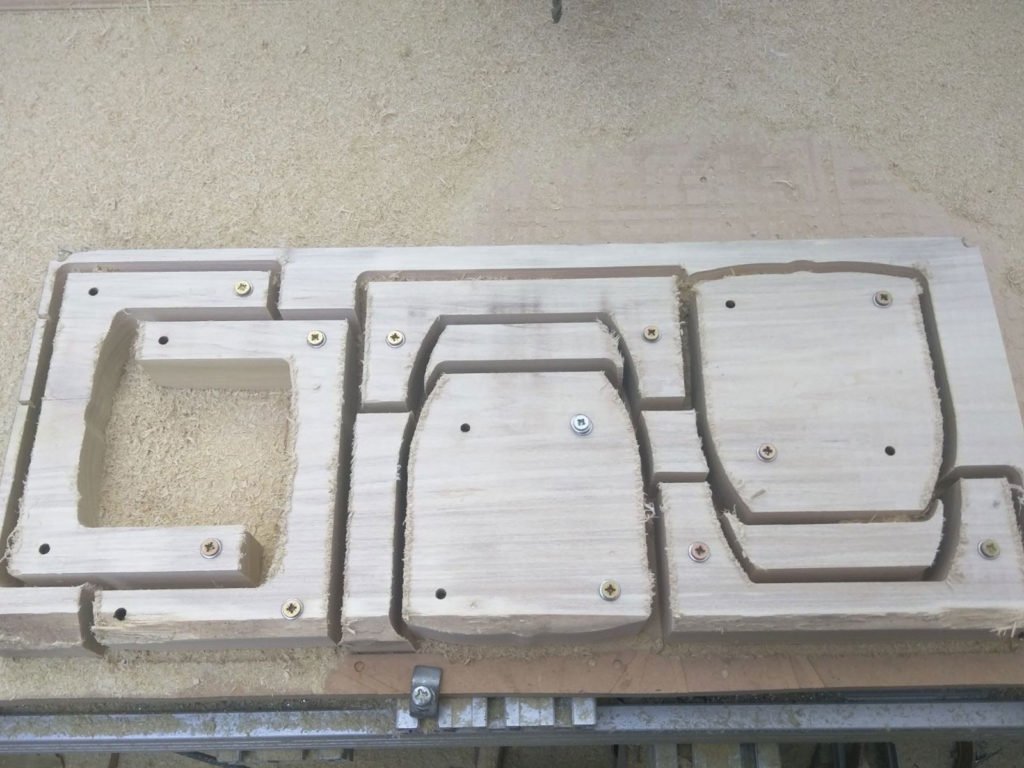

a. Start by routing mould parts. In this instance, we’ve glued two layers to produce required height

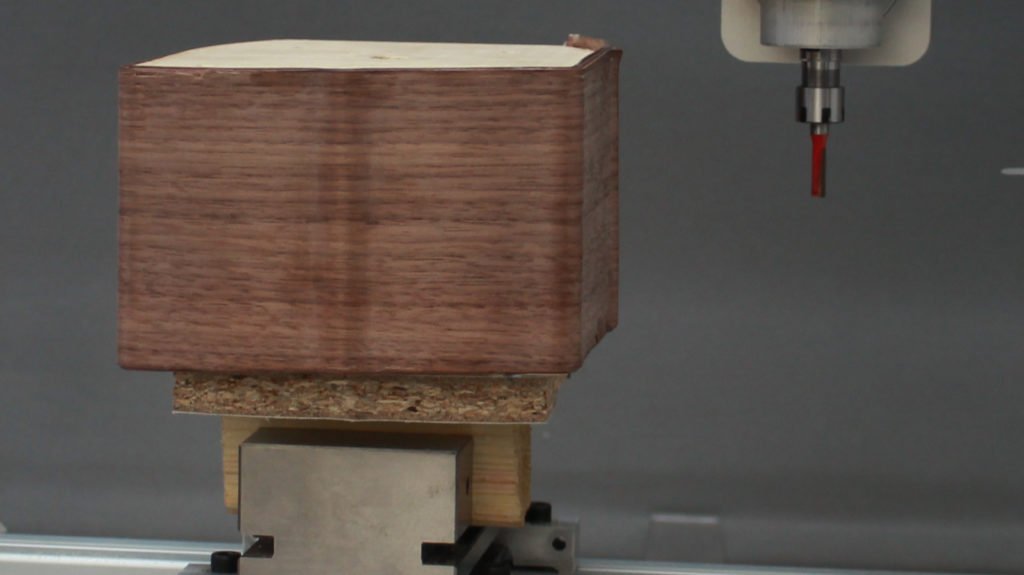

d. This particular walnut veneer mould is made of 7 layers. The direction of the grain alternates between the layers for structural integrity. The inner side of veneer to be glued only around edges, the outer – top side of the veneer doesn’t require any glue.

b. A three-piece mould is made, a central piece is also a machining jig.

e. The mould is clamped. Drying time varies, depending on the glue used. It’s important not to get glue on the top layer of the mould to avoid mould getting stuck once dried.

c. The mould is ready. The next step would be to prepare veneer sheets ready to go into a mould.

f. Once the clamps are taken down, this is how the dry mould would look like from below.

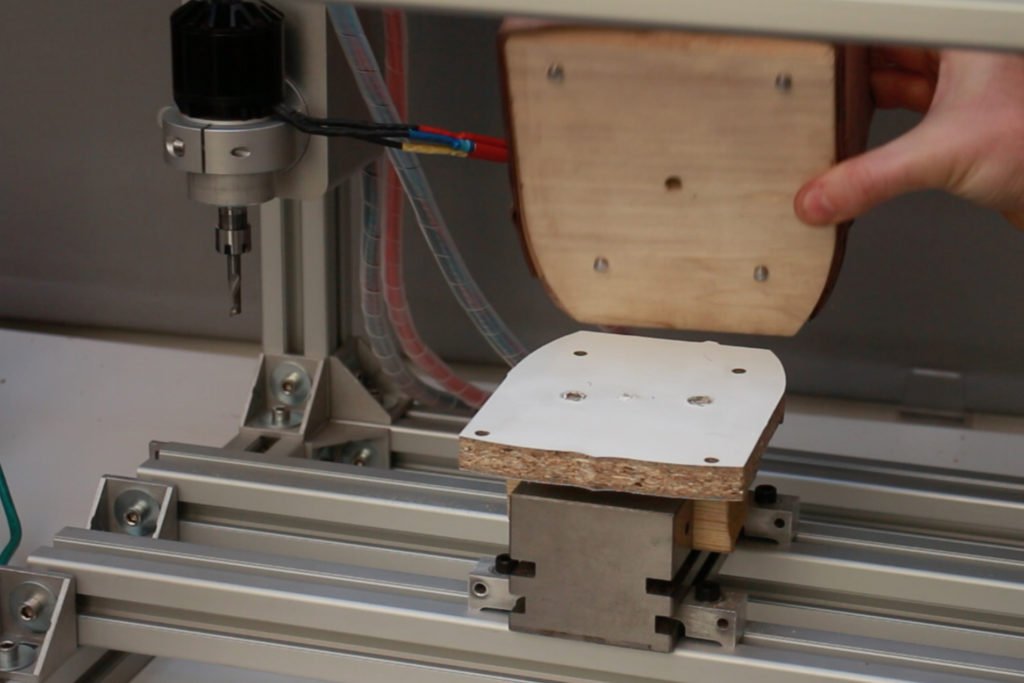

Prepare the jig and fixtures

The bottom of the jig fits into a vice. Home X,Y,Z and set to zero (see support on how to home your machine). Drill four holes to place the jig. Make a note of one of hole location (X,Y) and move 3dmodel according to X,Y position of a particular hole, but keep the 3dmodel Z at zero.

The mould fits into a lower part of the jig and is positioned with four index round bars.

The mould is fixed to the bottom part of the jig with a screw through the pre-drilled hole. Once you place the blank – jog the Z-axis to the top of the blank and set it to zero. The X,Y,Z is now positioned. The jig and 3d model are aligned.

File Setup

Material: Layered Walnut Veneer

Approx machining time: 10min

Trimming pass 01/02 5-axis simultaneous; 5mm carbide Router bit at 15,000RPM, feed 4000mm/min (157ipm) DOC 2mm (0.078n)

Lens pass 5-axis simultaneous; custom lens groove at 15,000RPM, feed 4000mm/min (157ipm)

Mill it

Cut out the form off the tabs, clean the edges with a fine sandpaper, apply a coat of tung oil.